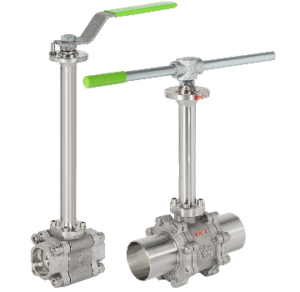

Ball Valves

Our ball valves are renowned for their exceptional performance and durability, providing reliable, tight shut-off even for the most demanding applications. Made from high-quality materials such as 316 stainless steel, brass, Monel, Hastelloy 276, and other exotic materials, they are designed for long-term use and reduced maintenance costs. Explore our range of ball valves and feel free to contact us for assistance in finding the right product to meet your specific needs.

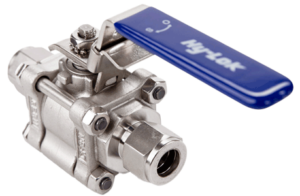

Hy-Lok 110 Series Low Pressure Ball Valves

Hy-Lok low pressure ball valves series engineered for reliable performance in a variety of industrial applications. Designed for general service, these valves offer exceptional durability and efficiency, making them an ideal choice for instrumentation and moderate-pressure systems.

Technical Specifications:

- Pressure Rating: Up to 3000 psi (207 bar)

- Temperatures: Up to 232°C (32° to 450°F)

- Orifice Range: 5-32 mm

- CV: 0.84 to 25.00

- Materials: 316 Stainless Steel, Brass, Monel Alloy 400, Hastelloy C-276, and Super Duplex

- A variety of End Connections: Hy-Lok tube fittings, male/female NPT and ISO threads.

Features and Benefits:

- Compact Design: Engineered for space efficiency without compromising on strength or functionality.

- Leak-tight Shut-off: Provides reliable sealing with low torque operation for ease of use.

- Blow-out Proof Stem: Provides safety against stem failure.

- Bi-directional Flow: Allows for flow in both directions.

- A variety of handle options.

For detailed specifications and more information about the Hylok 110 Series low pressure Ball Valves, please see the PDF. Please contact us, and we will help you find the most optimal ball valve for your application.

Hy-Lok 112S Series Ball Valves

Hy-Lok's 112 series is engineered for superior performance and reliability in various industrial applications. These valves are designed with precision, ensuring excellent flow control and durability.

Technical Specifications:

- Pressure Rating: up to 207 bar (3,000 psi) at 21°

- Temperatures: -54-149° C

- Orifice Range: 1.3-10.3 mm

- CV: 0,08-12

- Materials: 316 Stainless steel, Brass, Alloy 400 Monel

- A variety of End Connections: Hy-Lok tube fittings, male/female.

Features and Benefits

- Robust Construction: Made from high-quality materials for enhanced strength and longevity.

- Versatile Applications: Ideal for a wide range of fluids, including water, oil, and gases.

- Easy Operation: User-friendly design allows for smooth opening and closing.

- Leak-Free Performance: Advanced sealing technology prevents leakage, ensuring safety and efficiency.

- Compact Design: Space-saving design makes installation easier in tight spaces.

For detailed specifications on pressure ratings and performance metrics, please see the PDF. Please contact us, and we will help you find the most optimal ball valve for your application.

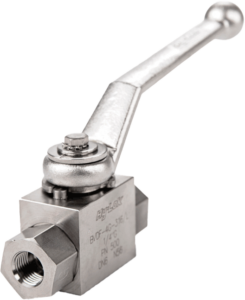

Hy-Lok 102 Series High Pressure Ball Valves

Hy-Lok 102 Series Ball Valves is engineered for high performance and reliability in demanding applications. Constructed with a one-piece forged housing, these valves are specifically designed for high-pressure environments. They serve as effective shut-off valves, particularly in applications where leak-free operation is crucial.

Technical Specifications

- Pressure Rating: Up to 6000 psig (413 Bar)

- Temperature Range: -54°C to 232°C

- Orifice Range: 4.2 mm (0.16") to 10.3 mm (0.4")

- CV: 0.06 to 6.42

- Material: Available in 316 stainless steel and brass

Features and Benefits

- Compact Design: Features a straight-through design for maximum flow rate and minimal pressure drop, optimizing system efficiency.

- Leak-Proof Shut-Off: The floating ball design guarantees a positive seal, preventing leaks even under high pressure.

- Versatile Connections: Available with various end connections including Hy-Lok tube fittings, NPT, and ISO threads for easy integration into existing systems.

For detailed specifications, please see the PDF. Please contact us, and we will help you find the most optimal ball valve for your application.

Hy-Lok T Series: Trunnion Ball Valves

Hylok T-Series Ball Valves are designed for high-performance applications, ensuring reliability and efficiency in demanding environments. With a robust construction and advanced features, these valves provide exceptional flow control and minimal operating torque.

Technical Specifications:

- Pressure Rating: Up to 10,000 psig (689 bar)

- Temperature Range: -17°C to 232°C

- Orifice 4.8 mm

- CV: 0,75 - 1,6

- Materials: 316 Stainless Steel and Alloy 400

- End Connections: Multiple options including Hy-Lok tube fittings, male/female ISO, and male/female NPT

Features and Benefits:

- High Pressure Rating: Ensures safe operation under extreme conditions.

- Durable Materials: Corrosion-resistant construction for longevity.

- Compact Design: Optimizes space without compromising flow.

- Low Operating Torque: Facilitates easy manual operation.

- Versatile Configurations: Available in both 2-way "Shut-Off" and 3-way "Switching" models.

For detailed specifications and more information view PDF. Please contact us, and we will help you find the most optimal ball valve for your application.

Hy-Lok P Series: Plug Valves

Hylok P-series Plug Valves are designed for reliable performance in demanding industrial environments. These valves offer exceptional flow control and durability, making them ideal for applications in oil & gas, chemical processing, and water treatment. With a range of customizable options, the Hylok P-series ensures optimal functionality tailored to your specific needs.

Technical Specifications:

- Pressure Rating: Up to 3000 psi (206 bar)

- Temperatures: -23°C to 206°C (-10°F -400°F)

- Orifice Range: 4,4-7,2 mm

- CV: – 1,4 – 7

- Materials: Brass, S316 and various exotic metals.

- End Connections: Hy-Lok Double ferrule fittings as well as IOS and NPT Threads.

Features and Benefits:

- High Durability: Engineered to withstand high pressures and harsh conditions.

- Versatile Applications: Suitable for multiple industries including oil & gas and chemical processing.

- User-Friendly Installation: Designed with easy-to-use end connections for quick setup.

- Low Maintenance Requirements: Reliable sealing mechanism minimizes wear and tear.

- Customizable Solutions: Available in various sizes and configurations for specific applications.

For detailed specifications and more information view the PDF. Please contact us, and we will help you find the most optimal ball valve for your application.

Hy-Lok 105 Series High Pressure Ball Valves

The Hy-Lok 105 Series Ball Valves are designed for exceptional performance in high-pressure applications, ensuring reliability and safety.

Constructed with a robust one-piece forged body, these valves provide effective shut-off capabilities, making them ideal for environments where leak-free operation is critical.

Technical Specifications

- Pressure Rating: Up to 10,000 psig (690 Bar) at 21°C

- Temperature Range:

PVDF Seat: -30°C to 130°C

PTFE Seat: -30°C to 180°C

PEEK Seat: -54°C to 260°C - Orifice Range: From 4,8 mm to 19 mm

- CV: 1.2 to 30

- Materials: Constructed from 316 stainless steel and alloy 400

Features and Benefits

- Compact Design: Optimizes flow rate with minimal pressure drop, enhancing system efficiency.

- Leak-Proof Shut-Off: The floating ball design ensures a reliable seal under high pressure.

- Versatile Connections: Compatible with various end connections, including Hy-Lok tube fittings, NPT and ISO threads.

For detailed specifications, please see the PDF. Please contact us, and we will help you find the most optimal ball valve for your application.

Hy-Lok SO Series Swing Out Ball Valves

The Hy-Lok SO Series Swing Out Ball Valves are engineered for a variety of demanding applications like chemical processing, oil & gas, pharmaceutical, power and utilities, biotech, and food and beverage industries. These valves provide a reliable, leak-free shut-off solution, ensuring safety and efficiency in your operations. Their innovative design allows for easy maintenance, minimizing downtime and enhancing productivity.

Technical Specifications

- Pressure: Up to 3,000 psig (206 bar)

- Temperatures: -28°C to 232°C

- Orifice: 4.8-22.2 mm

- CV: 1.2-40

- Materials: 316 Stainless Steel CF8M, Reinforced PTFE seats

Features and Benefits

- Live Loaded Design: Compensates for wear, pressure, and temperature changes, ensuring consistent performance.

- Swing-out Three-Piece Design: Allows for easy and fast replacement of seats, seals, and ball without major disruption in-line.

For detailed specifications and more information view PDF. Please contact us, and we will help you find the most optimal ball valve for your application.

Hy-Lok 115 Series Ball Valves

Hy-Lok 115 Series Ball Valves are designed for high-performance applications, providing exceptional sealing and flow control in hydraulic fluids, compressed air, lubricants, and fuel oil systems. With a robust construction and versatile design, these valves are ideal for various industrial environments, ensuring reliability and efficiency.

Technical Specifications

- Pressure: Up to 500 bar at 21°C

- Temperature: -23°C to 65°C

- Orifice: DN4-DN25 up to DN60 on request.

- Materials: 316 Stainless Steel or Carbon Steel

Features and Benefits

- Durable Construction: Made from high-quality materials, the Hy-Lok 115 series ensures longevity and reduces maintenance costs.

- High Flow Efficiency: The optimized orifice design allows for maximum flow capacity, enhancing overall system performance.

- Versatile Applications: Suitable for a wide range of fluids, making them perfect for diverse industrial sectors, including automotive and manufacturing.

- Standards Compliance: The 115 series complies with DIN 2353 and ISO 8434-1 standards, ensuring compatibility and reliability in various applications.

For detailed specifications and more information, view the PDF. Please contact us, and we will help you find the most optimal product for your application.

PG Flowteknik Ball Valve for Co2 Cooling systems

We introduce our All-Round Ball Valve, specifically developed for CO2 cooling systems. This valve is designed to ensure reliability and efficiency in demanding environments. With its robust construction and versatile features, it is an ideal solution for cooling systems.

Technical specifications:

• Pressure: Up to 2000 PSI

• Up to 137 bar at 90 °C

• Temperatures: -20 to +204 °C

• Orifice range: 11 - 49 mm

• Materials: 316 Stainless Steel / TFM4215

For more specifications and further information, view the PDF. Please contact us, and we will help you find the best product for your application.

Hy-Lok Cryogene valves

Hy-Lok ball valves can be used down to -196° C and for pressures up to 52 bar. The valves are constructed of austenitic stainless steel, and therefore they are suitable for handling a wide range of cryogenic media including LNG, oxygen, CO2, ammonia, LPG, methane, nitrogen and hydrogen. Reduced and full-bore are available from 1/2" to 1 1/2".

Hy-Lok´s cryogene valves Designed for easy in-line maintenance, they have access to service via the top of the valve. The product range is fireproof and designed for BS 6755 Part 2 standard..

- Maximum pressure up to 52 bar.

- Temperature from -196 - 120 degrees Celsius.

- Threaded connections from 3/8" - 1", Flange connections 1/2" - 1-1 / 2", Stuck welding connections 1/2" - 1 1/2"

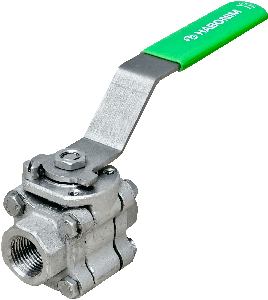

Habonim 47 Series Ball Valves

High-Performance Industrial Flow Control

The Habonim 47 Series three-piece ball valves offer exceptional reliability and versatility for demanding industrial applications. Engineered for endurance, these valves meet stringent international standards and provide high-flow capacity with tight shutoff.

Technical Specifications

- Pressure: Up to 155 bar (2250 psi)

- Temperature Range: -60°C to +260°C (-76°F to +500°F)

- Orifice Range: 11.15 mm to 111.10 mm

- CV: 6 to 1020

- Materials: Stainless steel, carbon steel, alloys, and more

Features and Benefits

- HermetiX™ stem seal: Provides ISO 15848-1 certified fugitive emissions control, enhancing safety and environmental protection

- Three-piece body construction: Allows for easy in-line maintenance and replacement of internal parts, reducing downtime

- Wide range of end connections: Offers flexibility for various installation requirements, including threaded, welded, and flanged options

- Compliant with ANSI B16.34 and API 6D standards

For detailed specifications and more information view PDF. Please contact us, and we will help you find the most optimal product for your application.

Habonim Metal Seated Ball Valves

Engineered for Extreme Conditions

Habonim's metal seated ball valves excel in the harshest industrial environments, offering unparalleled performance and durability. These meticulously engineered valves withstand extreme high temperatures, high pressures, and abrasive media, making them the ideal choice for critical applications where valve failures can impact plant efficiency, profitability, and safety.

Technical Specifications:

- Pressure: Up to ANSI Class 2500 (414 bar / 6000 psi)

- Temperature Range: -60°C to 650°C (-76°F to 1200°F)

- Orifice Range: 1/4" to 8" (DN8 to DN200)

- Materials: Stainless Steel, Carbon Steel, Special Alloys

Features & Benefits

- Advanced Surface Treatments: LTPN (Low Temperature Plasma carbo-Nitriding) for temperatures up to 400°C (752°F), providing triple the natural hardness of base materials

- High-Temperature Solutions: HVOF spray coatings for temperatures up to 538°C (1000°F) and specialized construction for up to 650°C (1200°F)

- Precision Engineering: Mate-lapped ball and seat sub-assemblies ensure high repeatability in sealing, low torque, and smooth operation

- Robust Construction: Withstands extreme temperatures and pressures, ensuring long-term reliability in demanding applications.

- Superior Sealing: Achieves EN12266-1 Rate B sealing through precise grinding and lapping processes, minimizing leakage risks.

- Versatile Coating Options: Tailored surface treatments and coatings provide outstanding resistance to corrosion and abrasion, extending valve lifespan.

For detailed specifications and more information, view PDF. Please contact us, and we will help you find the most optimal product for your application.

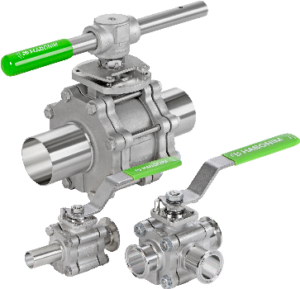

Habonim 48 Series Sanitary Ball Valves

Featuring HermetiX™ Stem Seal for Enhanced Contamination Control

These Ball Valves from Habonim are at the forefront of sanitary valve technology, offering exceptional cleanability and drainability. These ASME BPE-compliant valves ensure product quality and process integrity. The HermetiX™ Stem Seal features a patented FDA-approved polymer that eliminates leaks and enhances safety and productivity.

Technical Specifications:

- Pressure: Up to 400 bar (5800 psi)

- Temperature Range: -60°C to +260°C (-76°F to +500°F)

- Orifice Range: Available in sizes from 1/4" to 6" (6.35 mm to 152.4 mm)

- Materials: 316L Stainless Steel (forged, cast, or bar) for body and end connections; 316L Stainless Steel for Ball, Stem, bolts, nuts, and handle; FDA and USP Class VI compliant polymers or elastomers

- Additional material options include Hastelloy-C22 castings, AL6XN, Alloy 20, and other exotic alloys upon request

Features and Benefits:

- Full Bore Design: Valve port diameter matches tube inner diameter, ensuring complete drainage and preventing contamination.

- Low Ferrite Content: Standard metal parts with FE < 2% and controlled sulfur content (0.005% < S < 0.017%) provide superior welding quality and corrosion resistance.

- Complies with ASME BPE standards for biotech applications

- 4-year or 500,000 cycle maintenance-free warranty

- Optional forged 316L stainless steel with ferrite content less than 1%

- ISO 5211 mounting flange for easy automation

For detailed specifications and more information, view the PDF. Contact us to find the optimal product for your application.

Habonim Cryogenic Valves

Unrivaled Performance in Extreme Cold

Habonim Cryogenic Valve is a masterpiece of engineering designed for unparalleled performance in ultra-low temperature environments. This valve stands out with its superior sealing technology, robust construction, and exceptional temperature resistance, making it ideal for industries such as LNG processing and aerospace.

Technical Specifications:

- Temperature Range: -196°C to +65°C (-320°F to +149°F)

- Pressure Rating: Up to 420 bar (6,090 psi)

- Orifice Range: 8 mm to 200 mm

- CV Range: 2.5 to 1,400

- Materials: High-grade 316 Stainless Steel, Inconel, Monel

Features and Benefits

- Zero Leakage Design: The patented stem seal technology ensures safety and operational efficiency

- Fire-Safe Construction: Complies with API 607 standards for enhanced safety in critical applications with the following cryogens: Nitrogen, Oxygen, Hydrogen, Helium, Argon, Fluorine, Methane

- Low-Torque Operation: Reduces actuator size requirements, leading to cost savings

For detailed specifications and more information, view the PDF. Please contact us to find the most optimal valve for your application.

Ball valves are shut-off valves consisting of a valve body with a perforated ball that can rotate to open or close the flow. PG Flowteknik offers ball valves from two leading manufacturers: Hy-Lok and Habonim.

Ball valves are suitable for a range of applications and industries, including: Energy and district heating, Oil and gas industry, Food industry, Chemical and petrochemical industry, Pharmaceutical and food industry, Biogas and Power to X, Marine.

Ball valves are particularly effective for:

- Flow with media containing large particles

- Operation under both vacuum and pressure

- Handling corrosive and aggressive media

- Fast flow control.

Our ball valves are typically manufactured in the following materials:

These materials ensure optimal sealing and durability in various applications: Stainless steel S316, Brass, Monel Alloy 400, Hastelloy C-276, Super Duplex, Acid-resistant steel.

PG Flowteknik offers various types of ball valves:

- Manual valves with handles

- Automatic valves (pneumatic or electric actuator)

- 2-way and 3-way valves

- Control and indication devices for both manual and automatic ball valves

Connection options:

These various connection options allow the ball valves to be integrated into a wide range of existing systems and applications. The broad selection of connection options ensures that PG Flowteknik's ball valves can be adapted to different industrial needs and requirements. PG Flowteknik offers ball valves with a range of different connection options:

- Hy-Lok double ferrule fittings

- NPT threads

- ISO threads BSPT BSPP

- Flange connections

- Welded connections